What I learned in...

EMC & Packaging Lab Research Internship

1. Overview

During my internship at the KCC EMC & Packaging Research Lab, I explored semiconductor packaging processes, EMC (Epoxy Molding Compound) materials, and PCB/Solder Resist workflows. Through lectures and hands-on experiments, I gained practical understanding of how material properties influence the reliability and performance of semiconductor devices.

2. What I Worked On

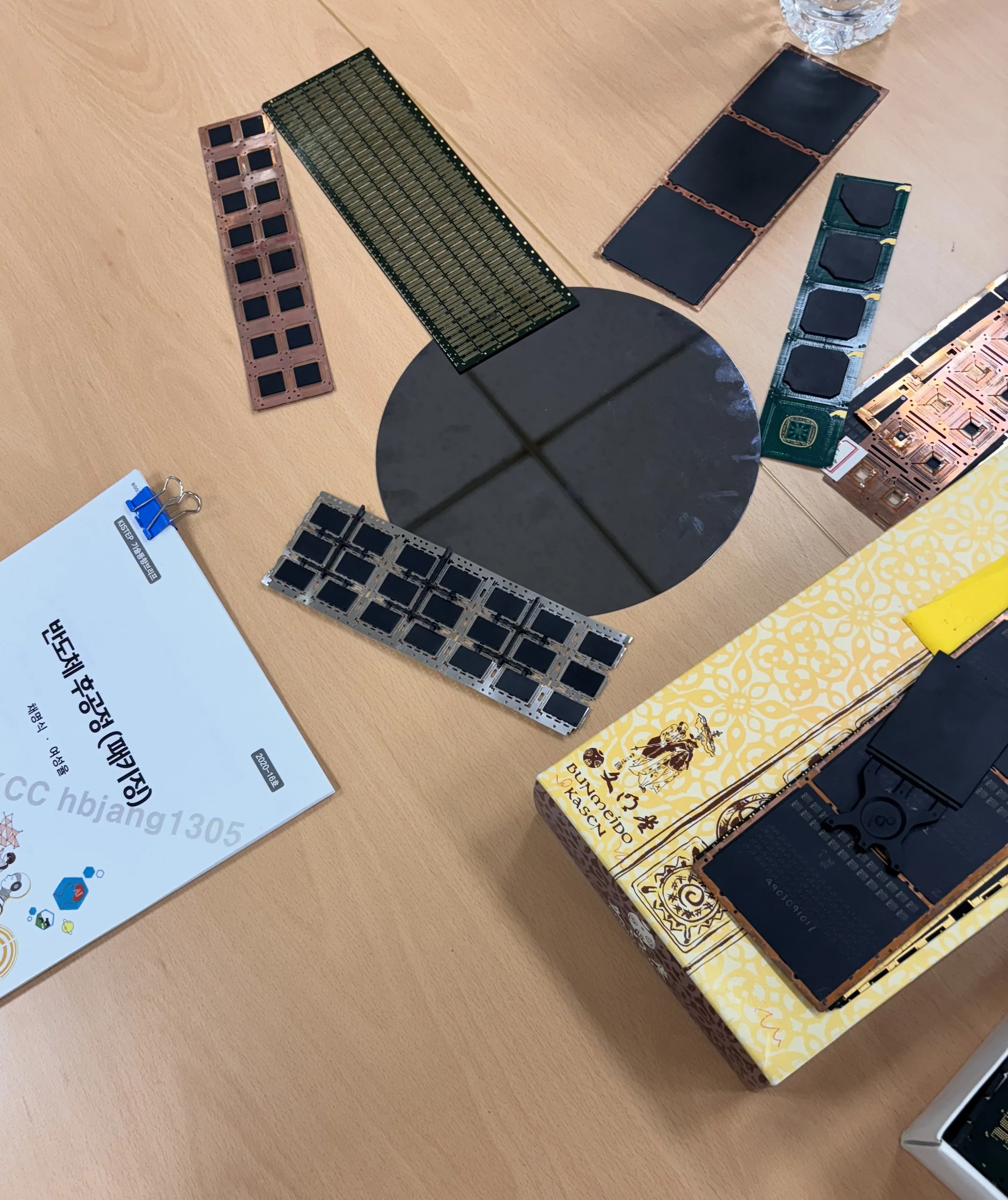

Semiconductor Packaging Fundamentals

- Wafer fabrication, oxidation, photolithography, etching, metallization

- Wire bonding vs. flip-chip bonding

- Packaging structure and reliability considerations

Epoxy Molding Compound (EMC)

- Learned EMC injection and granule molding processes

- Analyzed defect mechanisms: voids, wire sweep, incomplete fill, shrinkage

- Studied key material metrics: Spiral flow, Viscosity & gel time, Hot hardness, Thermal expansion (TMA)

Hands-On Experiments

- Operated molding equipment and measured EMC properties

- Tested flow, curing behavior, thermal expansion

- Observed and compared molding outcomes under different conditions

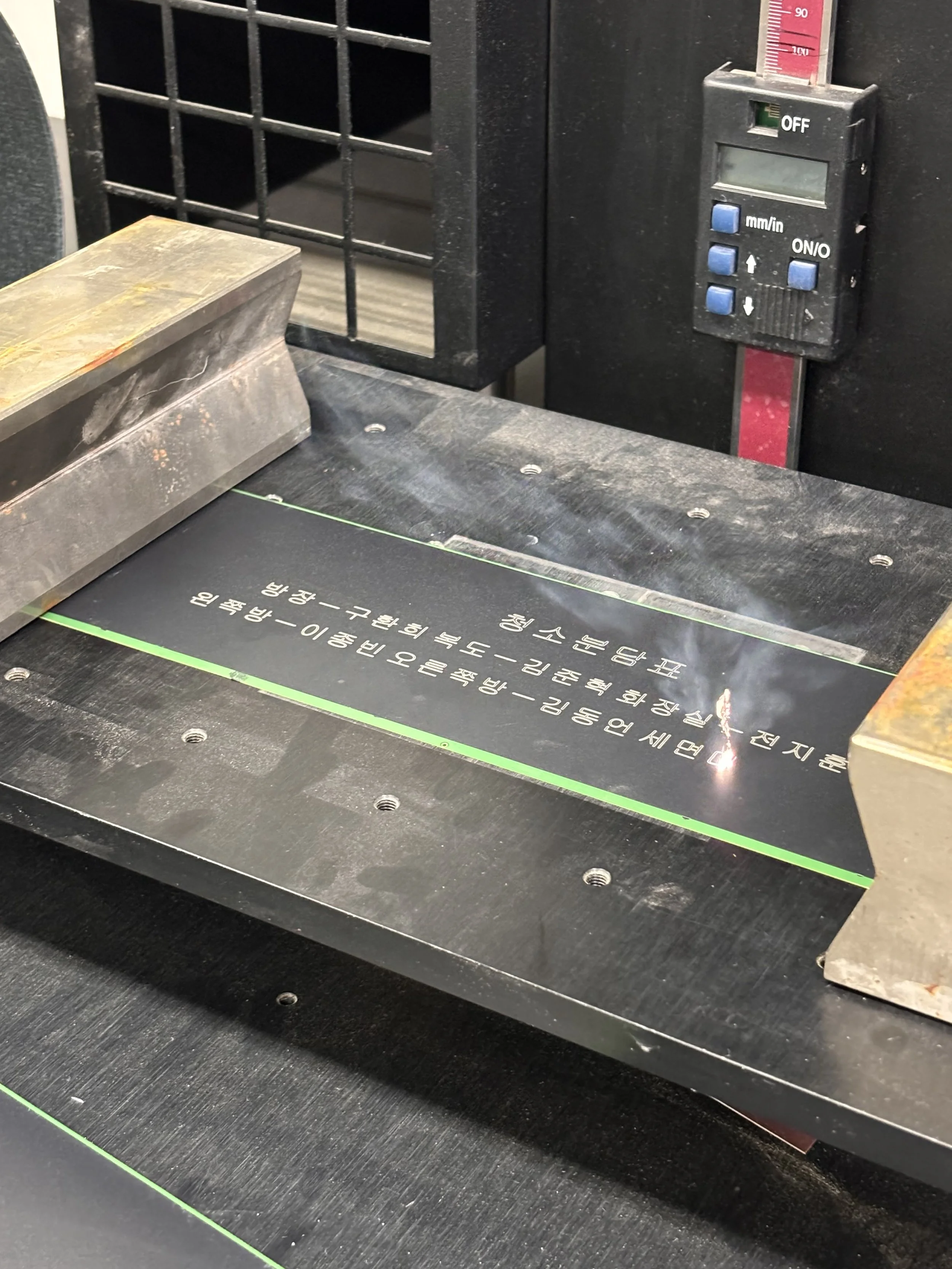

Solder Resist (SR) & PCB Fabrication

- Studied SR coating, UV exposure, development, post-cure

- Mixed SR ink and measured viscosity and curing temperature

- Designed and engraved PCB patterns using laser tools